Lab Facilities and Infrastructure

Thermal Laboratory

The Thermal Laboratory is fully equipped with various equipment that provide practical verification of basic principles of thermodynamics and thermal engineering, such as:

- Demonstration of various parts of an engine

- Demonstration of various systems of an engine

- Demonstration of a multistage reciprocating air compressor and explanation of its working

- Preparation of Heat Balance Sheet for an Internal Combustion Engine

- Analysis of performance characteristics of different engines under parametric variations

- William’s Line test to determine the friction power of an engine

- Operation of a single-cylinder water-cooled diesel engine

The laboratory consists of the following experimental apparatus:

- Single-cylinder 2-stroke petrol engine with rope brake dynamometer

- Single-cylinder 4-stroke diesel engine with hydraulic dynamometer

- 4-stroke four-cylinder petrol engine with electrical dynamometer

- Model of cut section for gear box

- Cut section of jeep with chassis

- Model of all engine parts

- Single-acting two-stage reciprocating air compressor

- Rotary air compressor

Fluid Mechanics & Fluid Power Laboratory

The Fluid Mechanics & Fluid Power laboratory of this department is equipped with different test rigs featuring state-of-the-art technology, exclusively for undergraduate-level student projects. The FM&FP laboratory provides facilities to conduct various tests, such as performance evaluation and operating characteristics of different machines.

Following are the major equipment available in this laboratory:

- Kaplan turbine test rig

- Pelton wheel turbine test rig

- Centrifugal pump test rig (variable speed drive)

- Gear pump test rig

- Impact of jet on vanes test rig

- Pitot tube test rig

- Rotameter, Orifice & Venturimeter test rig

- Bernoulli’s test rig

- Pipe friction test rig

- Flow measurement through V-notch & Rectangular notch test rig

- Reynold’s apparatus

Project Laboratory

The projects undertaken by the students of this department are displayed in this laboratory. It also serves as a dedicated space where students receive project training and work on the development of their projects throughout their course of study.

CAM Laboratory

The CAM Laboratory of this department is equipped with state-of-the-art computer workstations exclusively for undergraduate students. All systems are connected via Gigabit Ethernet to facilitate both internal and external communications.

The workstations consist of the following specifications:

- HCL Computer System with 1 GB DDR1 667 RAM

- PC2-5300 UNBUFF NON-ECC-B

- 160 GB 7200 RPM SATA/300 3.5″ HDD

- CPU: Intel Core 2 Duo E7300, 2.66 GHz

- 1066 MHz, 3 MB L2 Cache

- EXDW Motherboard

Advanced Manufacturing Laboratory

This laboratory is equipped with state-of-the-art machines, including non-conventional machines. Students can perform machining-related experiments and CNC part programming using the CAM Laboratory.

The laboratory is equipped with the following machines and systems:

- Electro-Discharge Machine

- CNC Flat Bed Lathe Trainer

- CNC Trainer Milling Machine – XL

- Automatic Servo Control Voltage Regulator

- Automatic Tool Changer

- CNC Milling Machine Tools

- Air Compressor

- HCL LCD Monitor and CPU with Standard Accessories

CAD Laboratory

The CAD Laboratory of this department is equipped with twenty-five state-of-the-art computer workstations exclusively for undergraduate students. All systems are connected to Gigabit Ethernet for both internal and external communications. Modeling and analysis software like AutoCAD, ANSYS, Pro/Engineer, and CFD Expert are installed in these workstations.

The workstations consist of the following specifications:

- HP 280 G3 DESKTOP

- Core i3 – 7th Generation (7100)

- Windows 10 Pro 64 Bit

- 4 GB DDR4 RAM

- 1 TB (7200 RPM) Hard Disk

- USB Keyboard & Mouse

- 19.5” LED

- 2GB Dedicated Graphics Card (NVIDIA® GT 710)

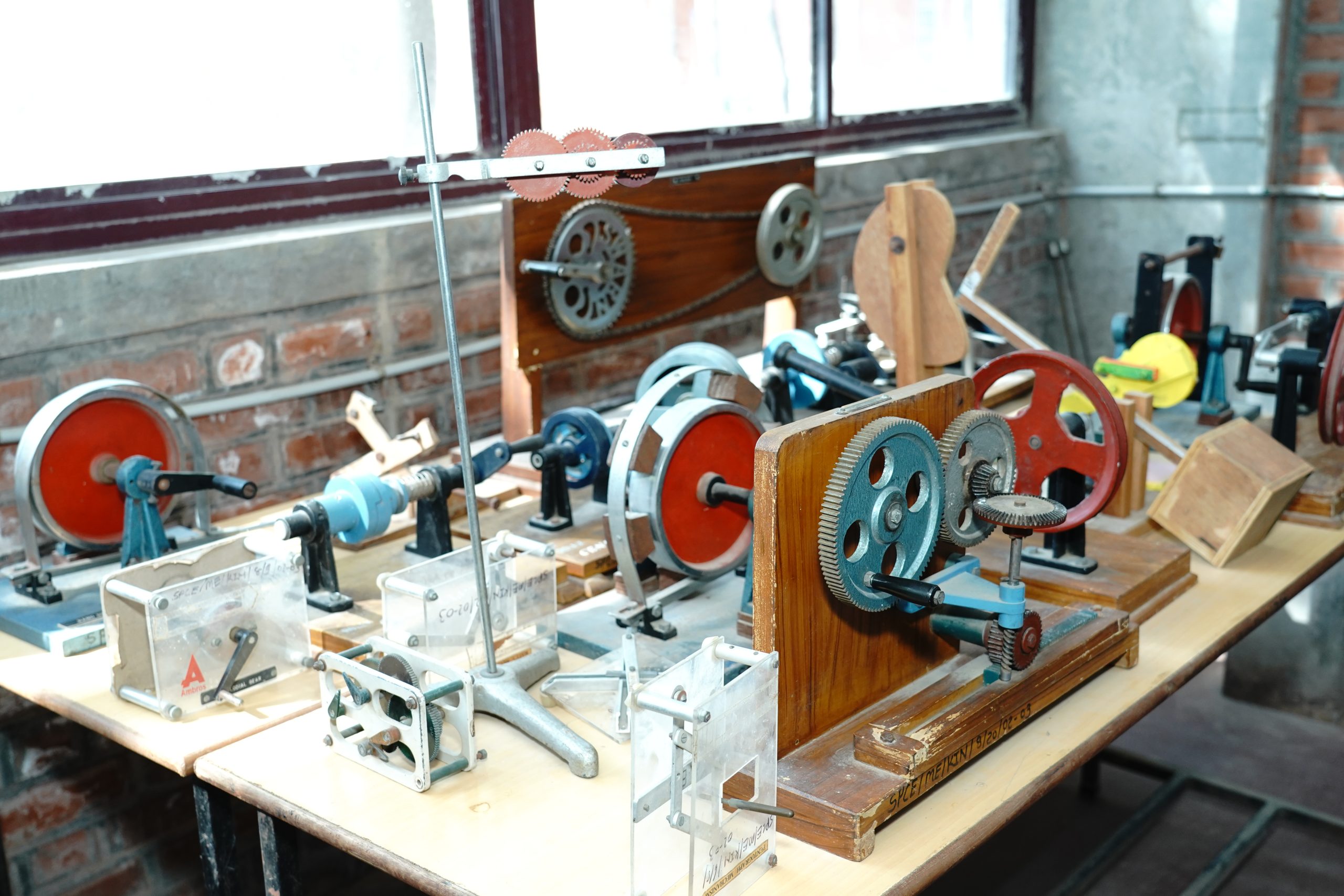

Kinematics of Machines Laboratory

Mechanisms form the basis of any machine, and they are an assemblage of rigid bodies that move relative to each other with definite motion. The Kinematics of Machines Laboratory features various models of brakes, clutches, kinematic pairs and mechanisms, cams and followers, pulleys, gears, and more to help students explore the function and working of mechanisms used in different machines.

The lab supports the study of different kinematic pairs for motion transformation and enables students to perform practicals related to Dynamics of Machinery.

This laboratory is equipped with the following apparatus:

- CAM Analysis Apparatus

- Horizontal Dynamic Balancing Machine

- Universal Vibration Apparatus

- Torsional Vibration Apparatus

- Universal Governor Apparatus

- Gyroscope Apparatus

- Whirling Speed of Shaft Apparatus

- Digital Stroboscope

Elements of Mechanical Engineering (EME) Laboratory

The EME Laboratory serves as a fundamental knowledge-sharing center for engineering students of all disciplines. It is equipped with thirty-four educational models that demonstrate various mechanical engineering systems and concepts.

Models of Boiler Section:

- Cochran Boiler

- Lancashire Boiler

- Babcock and Wilcox Boiler

- Locomotive Boiler

- Lever Safety Valve

- Spring Loaded Safety Valve

- Dead Weight Safety Valve

- High Steam and Low Water Level Safety Valve

- Water Gauge

- Pressure Gauge

- Hopkinson Type Stop Valve

- Feed Check Valve

- Blow-off Cock

- Green Economizer

- Sudgen’s Super Heater

- Steam Injector

- Fusible Plug

- Reducing Valve

Models of Internal Combustion Engine (I.C. Engine):

- Two Stroke Petrol Engine

- Four Stroke Petrol Engine

- Two Stroke Diesel Engine

- Four Stroke Diesel Engine

Models of Turbine Section:

- Pelton Wheel Turbine

- Francis Turbine

- Kaplan Turbine

- Axial Flow Runner

- Centrifugal or Radial Runner

- Gas Turbine (Turbojet Engine)

- Gas Turbine

- Gas Turbine Plant

- Air and Steam Pressure Turbine

Other Models:

- Compound Steam Engine

- Self-Priming Runner of Pump

- Hydro Electric Power Installation

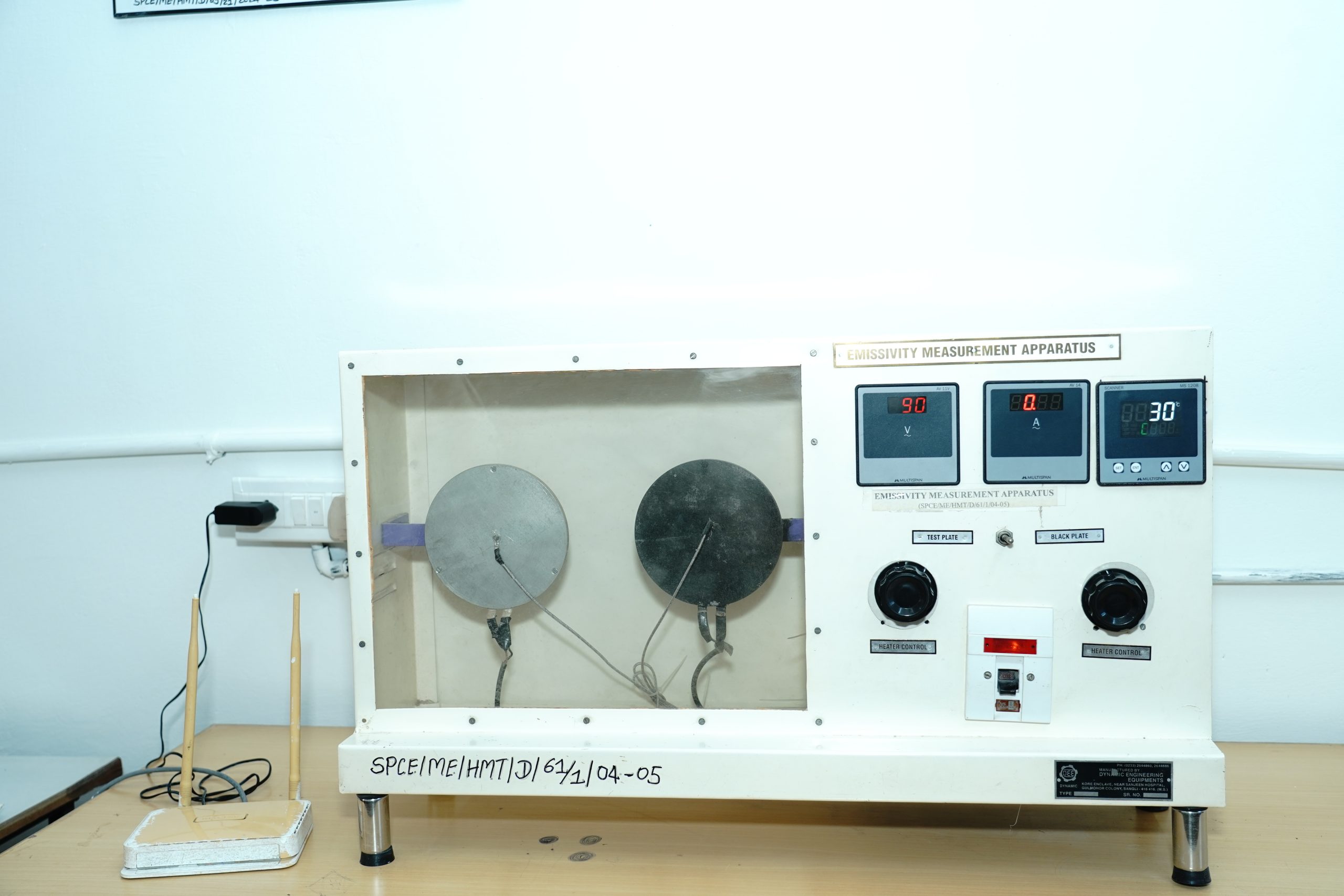

Heat Transfer Laboratory

The Heat Transfer Laboratory of this department is equipped with various types of apparatus that fulfill the testing requirements for different modes of heat transfer. This laboratory demonstrates fundamental principles such as Fourier’s law of heat conduction, natural and forced convection, Stefan-Boltzmann law, and the operation of heat exchangers in both parallel and counter flow configurations.

The laboratory consists of the following apparatus:

- Natural Convection Apparatus

- Forced Convection Apparatus

- Parallel Flow & Counter Flow Heat Exchanger

- Pin–Fin Apparatus

- Composite Walls Apparatus

- Stefan-Boltzmann Apparatus

- Emissivity Measurement Apparatus

- Thermal Conduction Measurement Apparatus

Department Library

The Department Library occupies a unique and vital place in the academic and research activities of the department. It serves as a central facility, supporting both students and faculty in their pursuit of knowledge and innovation.

The library houses a substantial collection of resources related to Mechanical Engineering, including:

- Reference books and textbooks on core and advanced topics

- ME/M.Tech dissertations and project reports

- Ph.D. theses

- Standard codes and manuals

- Data books, occasional papers, and academic journals

Additionally, the library features a well-equipped reading area that offers a conducive environment for study and research.

Material Technology and Measurement & Instrumentation Laboratory (Room No. WSG-5)

This laboratory is equipped with a wide range of instruments essential for both measurement and calibration tasks. It offers facilities for microstructure observation, various heat treatment processes on metals, and precision measurement of physical characteristics.

The key focus areas in this lab include:

- Microstructure observation and metallurgical analysis

- Linear, angular, and taper measurements

- Screw thread and gear measurements

- Surface finish measurement

- Straightness, flatness, squareness, and parallelism checks

- Machine tool testing

- Temperature and other miscellaneous measurements

Major equipment in the laboratory includes:

- Digital Infrared Thermometer

- Portable Surface Roughness Tester

- Ultrasonic Flaw Detector

- Triangular Metallurgy Gisal Microscope

- Refractory Furnace

- Double Disc Polishing Machine

- Carbon-Sulphur Determination Apparatus

Refrigeration & Air Conditioning (R&AC) Laboratory

The R&AC Laboratory of this department is equipped with fourteen experiment setups exclusively for undergraduate Mechanical Engineering students. This laboratory provides fundamental concepts and experimental exposure related to refrigeration and air conditioning systems.

The laboratory consists of the following experiment setups:

- 1/3 HP Refrigeration Test Rig – with additional water-cooled and air-cooled condenser

- Air Conditioner Test Rig (Capacity: 1.0 Ton)

- Vapour Absorption Refrigeration Test Rig

- Ice-Plant Tutor (Capacity: 20 kg/day)

- Working Model of Vortex Tube Refrigerator

- Mechanical Heat Pump Trainer

- Gas Charging Unit

- Freeze (BPL Make)

- Refrigeration & Air Conditioning Service Tools

- Refrigeration & Air Conditioning Components

- Air Cooler with Stand

- Second-hand Window Air Conditioner (1.5 TR)

- Cooling Tower Test Rig

- Centrifugal Fan Test Rig

P.G. CAD Laboratory

The P.G. CAD Laboratory is fully equipped with twenty computer systems exclusively for Post Graduate students. All systems are connected to Gigabit Ethernet for both internal and external communications. Students carry out research activities such as modeling and analysis using software like AutoCAD, ANSYS, Pro/Engineer, and CFD Expert, which are installed on these computer systems.

The systems consist of the following specifications:

- LENOVO/IBM 18.5” TFT Display

- Intel® Core™ 2 Duo CPU

- Windows 7 (32-bit operating system)

- 2 GB RAM

- 2 GB Hard Disk

- USB Keyboard & Mouse

Non-Conventional Energy Sources Laboratory

With the increasing demand for energy and the rapid depletion of conventional sources such as coal, petroleum, and natural gas, non-conventional energy sources like solar, wind, biomass, tidal, geothermal, and even waste-to-energy are gaining significant importance. These sources are abundant, renewable, pollution-free, and environmentally friendly.

In line with upcoming technologies, a high-tech laboratory for Non-Conventional Energy Sources has been developed. Students are actively engaged in developing innovative projects focused on the advancement of non-conventional energy technologies.

The laboratory consists of the following major equipment:

- Precision Pyranometer

- Surya Mapi

- Sunshine Recorder

- Shading Ring

- Flat Plate Collector

- Solar Water Still

- Solar Drier

Workshop

The workshop of this department is a space where theoretical knowledge acquired in the classroom is transformed into practical, real-world solutions. It houses a diverse array of tools and machinery, ranging from basic hand tools and measuring instruments to advanced, heavy-duty machines.

The various facilities available in the workshop are as follows:

Machine Shop: The main machine shop is well-equipped with:

- All Geared Lathe Machine with standard accessories

- Auto Stop Hydraulic Hacksaw Machine

- Shaping Machine with standard accessories

- Horizontal Universal Milling Machine

- Universal Radial Drilling Machine

- Bench Grinder

- Capstan Lathe with standard accessories

- Lathe Tool Dynamometer with digital multimeter

- Drill Tool Dynamometer

- Pillar Drill Machine with mechanical charge motor and accessories

- Power Press with mechanical charge motor and accessories

- All cutting tools and various machine tool attachments

Welding Shop: A well-equipped shop with:

- Arc Welding Machine

- Resistance Welding Machine

- Gas Welding Setup

- MIG Welding Setup

Foundry Shop: A complete setup including:

- Pattern Making Facilities

- Mould Making Facilities

- Electric Centrifugal Fan-Assisted Coal-Fired Furnace

- Tin Smithy Setup

Carpentry Shop: Equipped with basic carpentry vices and various hand tool sets.

Plumbing Shop: Equipped with basic plumbing vices and various hand wrench sets.

Drawing Hall

The Drawing Hall is fully equipped with various drawing instruments that help students develop and master the skills of engineering drawing. It offers a comfortable and resourceful environment with all the necessary amenities. Under the guidance of experienced faculty, students are taught the principles of engineering graphics. Practical sessions include projections of points, lines, planes, solids, development of surfaces, engineering curves, orthographic projections, and isometric projections.

The laboratory consists of the following equipment for Engineering Graphics:

- Drawing Board Hart Imperial

- Mini Drafter

- T-Square

- Instrument Box

- Drawing Pencils Set

- Set-Square (45° & 30°-60°)

- Circle Protector

- Scale (30 cm)

- Drawing Clips

- Eraser

- Sharpener & Emery Paper

- Drawing Sheet Container

- Scientific Calculator

- French Curve

- Charts for Engineering Drawing

- Geometrical Instrument Box

- Projection of Straight Line Application Models

- Models of Dissected Solids

- Models of Sectionalized Solids

The laboratory consists of the following equipment for Machine Design:

- Cotter Joint

- Gib & Cotter Joint

- Sleeve and Cotter Joint

- Knuckle Joint

- Flanged Coupling

- Hook’s Coupling (Double)

- Hook’s Coupling (Single)

- Flexible Coupling

- Claw Clutch

- Universal Coupling

- Oldham’s Coupling (Small)

- Oldham’s Coupling (Big)

- Box or Muff Coupling

- Split Muff Coupling

- Shafting General Bearing

- Open Truck Bearing

- Simple Bearing

- Bush Bearing

- Thrust Bearing

- Plummer Block or Pedestal Bearing

- Foot Step Bearing

- Hemispherical Section Models of Screw Threads

- Hemispherical Section Models of Screw Thread Nuts

- Standard Bolt

- Bolts of Four Types

- Foundation Bolt

- Locking Arrangements of Bolts